An effective quality assurance program is essential to not just measuring, but to continuous improvement in janitorial performance. Smarter inspections offer better quality control.

An effective quality assurance program is essential to not just measuring, but to continuous improvement in janitorial performance. Smarter inspections offer better quality control.

Today, advancements in technology have allowed for useful alternatives with much lower costs than in the past. Smart Inspect is one of those programs. Smart Inspect software is configured to your facility’s exact cleaning specifications. Everything is digital! With only a touch on the device’s display screen, you can select locations, buildings, rooms and area types specific to your facility.

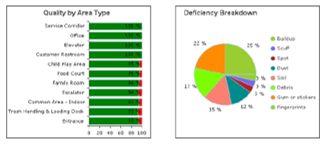

Janitorial maintenance details are imputed into a handheld device and then uploaded to a PC. Results are provided to the Account Manager so they can review the findings with the crew, and take corrective action, if necessary. A copy is also given to the client. This is a valuable tool for assisting in building maintenance continuous improvement. Smart Inspect has key performance indicators related to a percentage of tasks performed in an acceptable manner. Other features of this software include crew scheduling, estimating, job completion monitoring and job tracking.

The best way to prevent problems is to build a quality assurance cycle into your cleaning program. Part of the cycle will be to perform routine cleaning inspections, but you should also then spend time going through the data that you have collected. Take advantage of any available reports and drill down into the data to see what the true root causes of cleaning quality issues might be. Once you know what the issues are, then make the necessary corrections and adjustments within your program or staff. Most likely, some issues will pop up each month due to many different factors, but by maintaining a quality assurance cycle with Smart Inspect, the most major issues should be put to rest and prevented.

In addition to rigorous quality assurance programs and supervisor spot inspections, our regional managers visit each facility at least once per month for onsite visual inspection to ensure the highest standards are not only met but exceeded.